LEWIS OFFICE DESK

Shaker Style meets the sleek lines and narrow proportions of the Japanese Minimalist design aesthetic – The Lewis Collection strikes the perfect balance between simplicity and elegance.

DESIGN & CONSTRUCTION

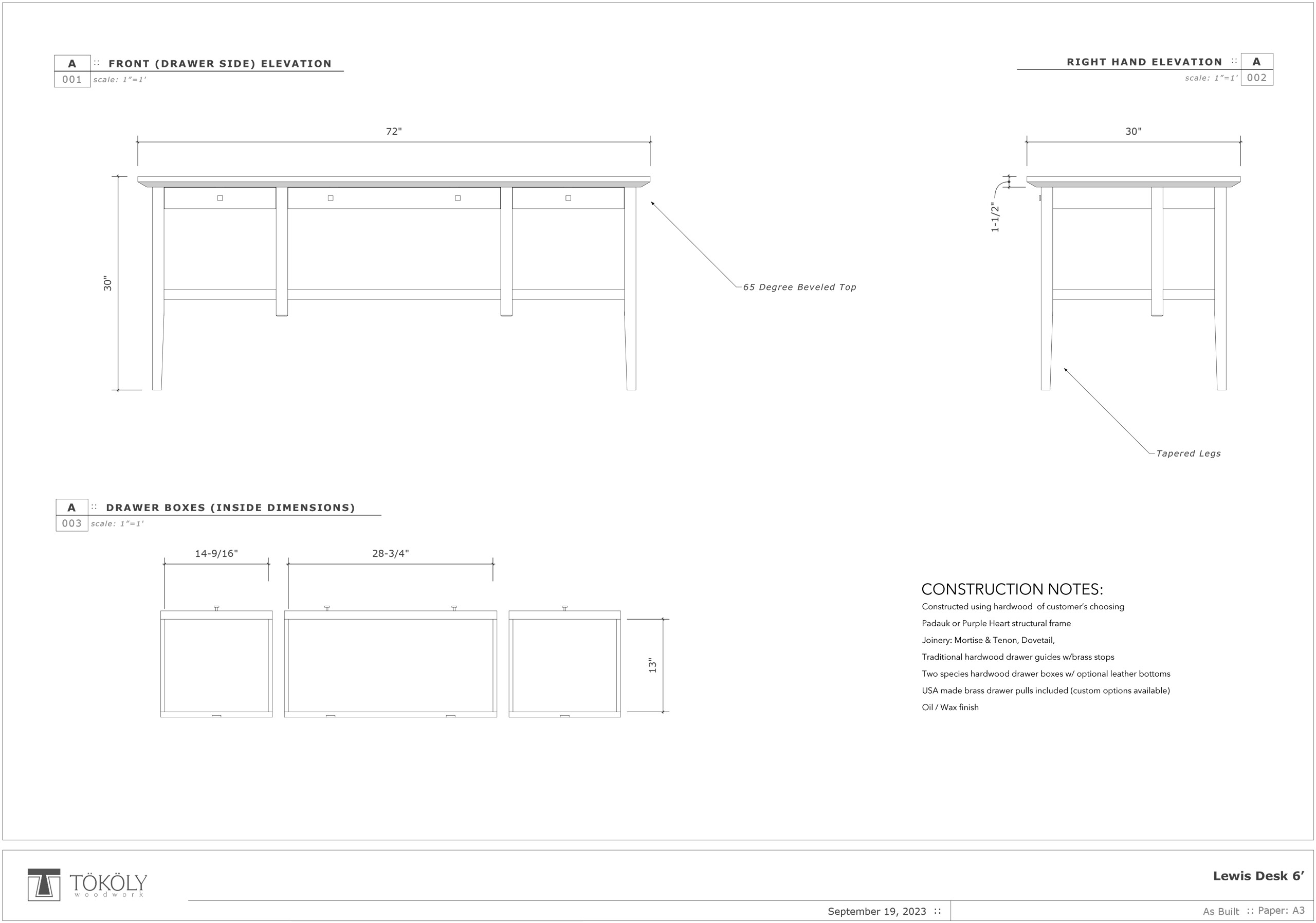

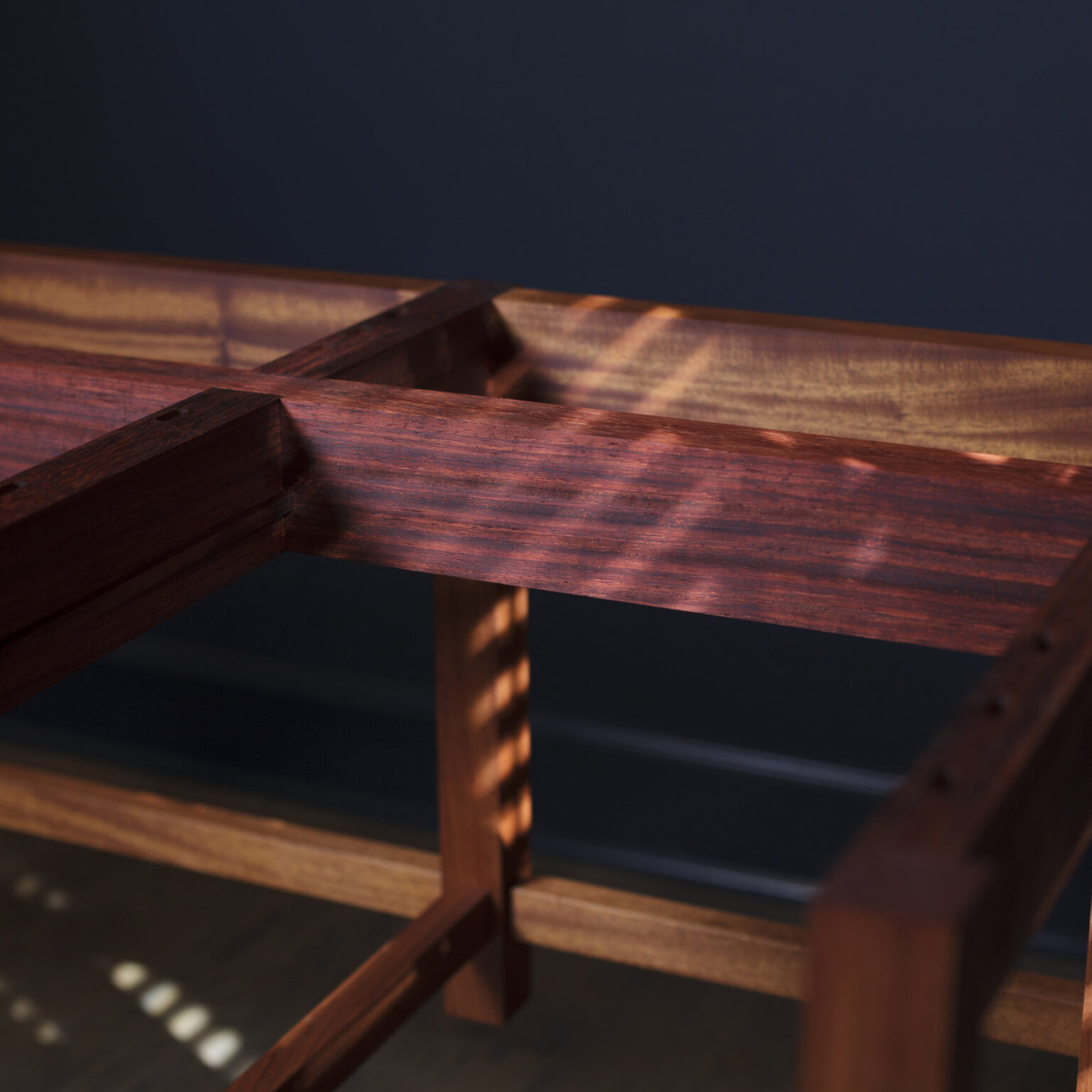

Hidden under the 1-½" thick solid hardwood beveled top, resides three floating drawer boxes; made possible by a muscular Padauk cantilevered frame joined by cross halving joints with housed shoulders. The rails, styles and drawer faces are all made from continuous cuts of the lumber giving every face or angle perfectly flowing lines of wood grain.

The joinery hidden beneath the top and behind the drawers is as beautifully constructed as any of the outwardly visible components. Beautiful joinery is well made joinery. Well made joinery is strong joinery.

HAND DOVETAILED DRAWER BOXES

Each drawer box is made from two species of hardwood lumber and joined front and rear using hand cut half-blind dovetails. The drawer bottoms are constructed using the primary hardwood of the customer's choosing and can be optioned with Wickett & Craig English Bridle Leather.

The drawers move on traditional hardwood slides and have hidden but removable hardwood guides/stops (easily fastened/removed from the rear with knurled brass thumb screws).

The inside of each drawer is drilled for brass machine screws and countersunk washers that will accept any style drawer pulls the customer prefers.

INQUIRE

Every Lewis Desk is handmade to order and constructed using your choice of solid hardwoods (shown with a combination of Honduran Mahogany, Black Walnut and Padauk hardwoods).

Please fill out the adjoining form and we'll respond as soon as possible to discuss the custom details for your Lewis Desk.

Email directly: info@tokoly.com